Total Seal: Ring Types 101

When it comes to building an engine, whether it’s for a weekend cruiser, Saturday night on the dirt track or a nitrous injected drag car, you need to do your homework on the thousands of engine parts offered by the aftermarket and racing industry. Crankshafts, pistons, cylinder heads, bearings, rods and piston rings all need to be selected to match your application.

The good news is that most race parts manufacturers are available to walk you through the selection process. This is especially important as power levels rise and you need to ensure each component must be designed to handle your specific application. Piston rings are a prime example as there are many different materials, coatings and designs available depending on the engine characteristics and how it will be used.

Selecting the right set of piston rings is imperative to your engine’s performance. Total Seal offers a number of ring designs, materials and coatings available for stock rebuilds up through NASCAR Cup engines.

Total Seal, based in Phoenix, Arizona, specializes in piston rings and piston rings only. They’re known for their Gapless Ring design but also have a number of specialized ring configurations created for specific performance and racing applications. We touched base with Total Seal to get an overview of a few of their patented ring designs and materials offered for different performance applications. However, it’s not as easy as just clicking on a part number as many applications are best suited to mix some of their different designs or materials. The following information is meant to be a guide to understand some of their offerings before making a call to one of their experienced techs for your specific application.

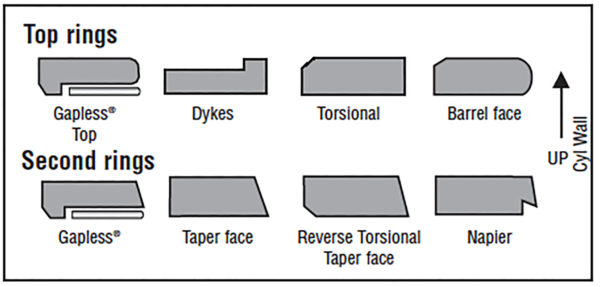

When talking piston rings, there are several common forms for the top and second ring. This chart illustrates the profile of the Total Seal Gapless Rings as well as different forms available.

The most common ring set begins with their Classic Race (CR) set. This is a ductile iron plasma moly top ring with a conventional second and standard three piece oil ring set. These sets are ideal for street and mild race applications up to 10.5:1 compression.

The Total Seal Gapless ring design features a main ring with a machined recess where the smaller rail assembly fits. Together, the patented ring eliminates blow-by to produce a more efficient seal and improved performance.

There are options for lower tension oil rings and a step up in performance net you their CS series which features their Advanced Profiling top steel ring and a Napier style second ring. The CS ring set can be used in nitrous applications up to 400-horsepower or with up to 35-lbs of boost. Anything above those levels are recommended to upgrade to their M2 tool steel top ring or go with their proven Gapless top ring.

The next level for increased power on a naturally aspirated engine, or even a mild nitrous or boosted street engine, would be the TS banner. TS sets feature an AP top ring with the support of a Gapless second ring and standard tension three piece oil ring. Options in this group include a ductile iron conventional top ring or using their Gold Power low tension oil rings which offer 40% reduction in tension compared to the standard tension rings.

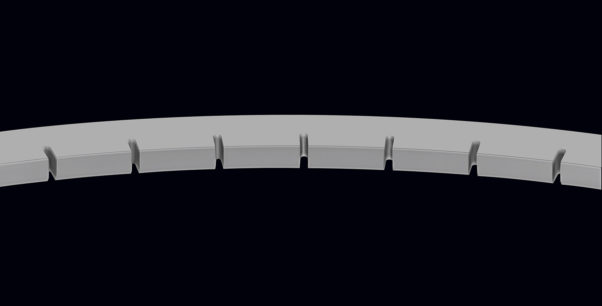

Another unique designed from Total Seal is their Total Conform series of rings. Thanks to the unique radiused slots, the ring is able to conform to cylinder distortions creating an improved seal.

Their preferred Gapless design is available as an MS series which includes an AP steel Gapless top ring, a conventional or ductile iron Napier cut second ring and a standard oil ring package. Options in this group include low tension oil rings or a Maxseal set which includes a ductile iron Gapless top ring. The full-on Advanced Profiling steel rings are the next step in performance and are now available in sets by the cylinder’s bore size. These rings are custom manufactured to tight tolerances and are coated with aerospace low-friction chemistry to reduce wear. Total Seal offers the AP line in custom sizes by request.

If you’re restoring a rare, vintage engine or building an all new mountain of a motor with copious amounts of boost, Total Seal will have a ring for you. Think you have a unique bore size or requirement? Give them a call!

At this point, things under the hood are getting pretty serious and are at the higher end of the motorsports chart of performance. When it comes to extreme use of nitrous and boost such as in Pro Mod racing, the M2 Tool Steel Top Rings fit the bill. These rings are available in conventional or Gapless designs and can be had with or without a C-69 proprietary face coating with incredible anti-friction properties.

As obscene cylinder pressures come into play with aluminum blocks and thinner cylinder walls, the Total Conform ring needs to be considered. It’s hard to picture, but imagine the cylinder wall actually distorting due to pressures and extreme temperatures. These distortions result in a leak area between the ring and the wall. This is where the Total Conform ring technology comes into play.

Thanks to precise radial notches placed on the inside of the ring, the face will actually conform to these minor distortions in the cylinder wall to seal in the combustion pressures. The Total Conform technology can be ordered as an upgrade in many of the ring series including the AP, M2 and the premiere Diamond Finish rings. Gas porting of the top ring is also available on all of the Total Seal’s offerings. This machining procedure uses the combustion gases to help push the top ring towards the cylinder wall to improve sealing.

Diamond Finish is hands down the most precise, lightest ring you can fit to a piston. If you were to zoom into the top of a typical production iron ring, you’d notice a sawtooth like finish with an axial thickness of about +/-.0005-inch. A Diamond Finish ring undergoes a proprietary manufacturing and lapping process to finish the ring with a tolerance held to +/- .000050-inch (that’s fifty-millionths of an inch)! On top motorsports engines, this finish is imperative to sealing and performance, plus the rings are incredibly lightweight which has a direct effect on the acceleration of an engine. As icing on the cake, Total Seal offers a friction and heat reducing PVD coating for these extreme applications.

It’s difficult to cover all of the differences and technology available from Total Seal, but hopefully this overview provided a slice of the options available for your next engine. To ensure you make the best choice for your build, it’s always best to speak to one of the techs at Total Seal by calling 623-587-7400. Give them a call, they’re ready to help any way they can!

COMPANY DETAILS |

|

|

Company |

Total Seal |

|

Website |

|

|

Connect |

|

|

|

|

|

Phone |

(800) 874-2753 |

|

Address |

22642 North 15th Avenue |

|

Phoenix, Arizona 85027 |

ABOUT Total Seal®

In late 1999 we moved into our new 32,000 square foot facility in Phoenix, Arizona. It houses the latest in research and development equipment, manufacturing machinery and technology focusing on developing and manufacturing piston rings for any and all applications.Our rings continue to show up on the world’s fastest, from NASCAR and IndyCar, from marine to drag racing, oval track to off road – nobody builds piston rings that seal better than Total Seal.